CNC concept is the basis for “manufacturing automation” leading to robotics where every movement is controlled by stepper motors. Skills development in CNC Programming, control, movement will open wide range of manufacturing automation applications which are essential for high level of productivity, repeatability and accuracy. CNC-based systems are applied widely in every manufacturing process involving welding, cutting, assembly, packing in Automotive, Medical, Process control and advanced areas like Space and Nuclear. Leading industrialised nations use manufacturing automation to further their technical advancement at lower manufacturing cost.

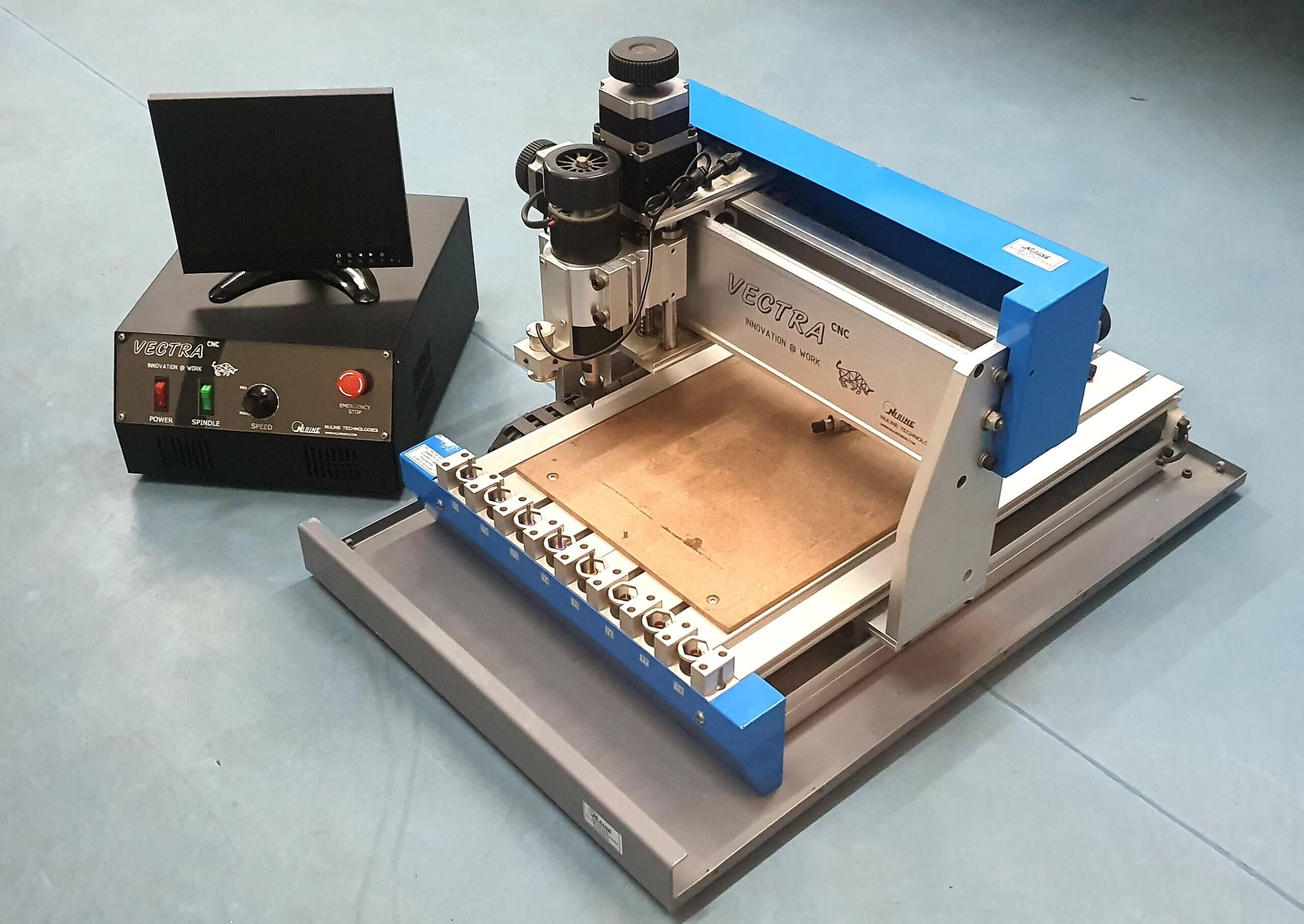

What is Nuline Vectra CNC?

Nuline Vectra CNC is a 3 Axis controlled CNC machine and can be extended to 4 Axis. The system has a large work area of 420mm x 300mm x 55mm and the 500W spindle can deliver good machining performance to work on commonly used materials. The controller can be easily programmed using standard G codes for various operations. One can swiftly get the job done in Nuline Vectra CNC on time. Reasonable safety features protect the job, machine and user from accidental movements.

Comes with free bundled-in professional-grade CNC Software

Mach3 turns a typical computer into a CNC machine controller. It is very rich in features and provides a great value to those needing a CNC control package. Mach3 works on most Windows PC’s to control the motion of motors (stepper & servo) by processing G-Code. While comprising many advanced features, it is the most intuitive CNC control software available. Mach3 is customisable and has been used for many applications with numerous types of hardware. Copper CAM for CAM processing.

- Converts a standard PC to a fully featured 6 Axis CNC controller

- Allows direct import of DXF, BMP, JPG and HPGL files

- Visual G-Code display

Nuline VECTRA controller box is a bridge between CNC software and CNC machine. Vectra is equipped with 3 Linear axis (X,Y and Z) and can be extended to 4th axis – angular A – axis. Controller has the dedicated emergency stop push switch and supports safety limit switch by sensing the signals from limit switches from all the 3 axis. The controller comes with RPM knob to maintain the speed of spindle for different applications.

Nuline VECTRA controller box is a bridge between CNC software and CNC machine. Vectra is equipped with 3 Linear axis (X,Y and Z) and can be extended to 4th axis – angular A – axis. Controller has the dedicated emergency stop push switch and supports safety limit switch by sensing the signals from limit switches from all the 3 axis. The controller comes with RPM knob to maintain the speed of spindle for different applications.

Nuline VECTRA offers GAUGE BLOCK probing to set the tool depth.

Nuline VECTRA Tabletop CNC Specifications:

| Working area | 420 x 300 x 55 mm |

| Driving units X/Y/Z axis | 1204 Ball screw with 2 Phase Hybrid Stepper Motor |

| Rail | Linear bearing on Chrome plated shaft on all 3 axis; e Hardening 61HRC |

| Spindle Motor | 500W, 11000 RPM |

| Maximum Operating Speed | 4000 mm/min |

| Engraving Speed | 3000 mm/min |

| Tool change | Semi-automatic 8 stations tool changer, software controlled tool changer for tool pick up and drop |

| Repeat Positioning Accuracy | 0.05mm |

| Spindle Collet Type | 1/8 inch, 3.175mm; ER11 |

| Camera Vision | Camera view and review software driven with camera monitoring station |

| Controller | 4 Axis CNC controller with spindle speed control, Limit Switch control and Depth control input |

| Software | MACH 3, CopperCAM |

| Drill size (min—max) | 0.6 — 3.1 mm |

| Computer Interface | Onboard Parallel Port |

| Operating Voltage | 220V / 50Hz / 500W |

| PC Computer Hardware | Fully Loaded PC computer having on board parallel port with 22 inch monitor and Preloaded Mach3 and copper CAM software, |

| Material | PVC, PCB, Acrylic, Wood, MDF Board, Non-Ferrous Metal |

| Application | Rapid Prototyping, Technology Research, Teaching, Student Project, PCB Engraving/Milling, Model making |

Applications of Nuline VECTRA portable CNC Machine

The time it takes to develop a new product from design to manufacturing is critical in an on-demand world. This is especially true in the design phase. Traditionally, a model is designed and the assembly of a prototype is outsourced to a third party. This method is time-consuming and costly. As a result, more manufacturers are turning to in-house rapid Prototyping, such as using a Prototyping CNC machine for various applications.

Traditional outsourcing can take a week or more for a prototype to arrive due to transit time. In addition, internal development can cause more lag. Due to the time and expense involved, educational institutions and R&D centres hesitate to request a prototype until they have something close to a finished model. Time and expense are less of an issue for in-house prototyping, as a physical model can be built on-site the same day. This can significantly reduce the timeline of overall development.

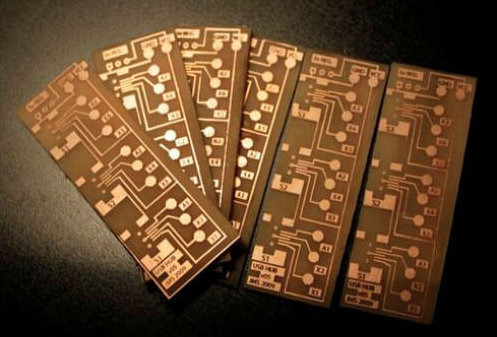

Looking for a fast PCB Prototyping Machine?

Especially during development, fabricating a prototype quickly and with flexibility is key. This allows developers to test ideas and easily make changes. The Rapid Prototyping method turns a sheer idea into a sample circuit board, which is ultimately used to manufacture the new product.

Once the circuit board – single or double-sided, has the conducting paths, the circuit is tested. If faults are detected or changes are requested, the data layout can quickly be modified. Thus, a new prototype is created quickly and easily, without the use of chemicals and your data always remains protected and confidential.

Vectra Distributor for North India:

Ambition Technologies

17, First Floor , Pocket 2, Sector 24

Rohini, New Delhi – 110085 India

Tel: +91 81781 92187

Email: sales@ambitec.org