Nuline’s expertise lies in designing and manufacturing Electronic Systems as per customer specifications.This includes test systems, load boxes, breakout boxes and cable harnesses.

We have had innumerable success stories from our customers regarding our proto development. Nuline Technologies is your one-stop solution for any proto electronics system development, specially for the automotive industry.

With an unparalleled in-house R&D capability to understand end-to-end concept-to-product development needs, we can assure you that your specifications will be converted to a functional product in no time with no compromise on quality.

All stages of product development are addressed by our qualified in-house team.

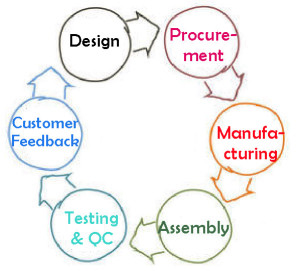

The stages of product development are:

- Circuit analysis and BOM generation

- Schematic validation and design database creation

- Component sourcing

- Mechanical layout design

- Assembly and wiring diagrams

- PCB layout design and fabrication

- Component assembly

- Integration and testing

- Quality control and test reports

- Logistics management and timely delivery

Range of systems developed by us include:

- Automotive engine simulators

- Body simulators

- Load boxes – inductive and resistive

- Relay load boxes

- Breakout boxes

- Endurance test load systems

- Wiring harnesses

- Cables and sub-assemblies

- Test PCBs

Development process:

Nuline has developed over 1,000 systems with varied specifications and these have even been exported to different developed countries. These systems have been developed conferring to the highest quality standards and having used high reliability components to ensure uninterrupted performance.

All components strictly follow the specifications as laid out in the Bill of Materials by the customer. These are sourced directly from manufacturers through authorised distributors to ensure reliability of the component.

All components strictly follow the specifications as laid out in the Bill of Materials by the customer. These are sourced directly from manufacturers through authorised distributors to ensure reliability of the component.

Stage-wise inspection by our team ensures that there are no errors in assembly.

We use a wide range of inspection systems and test jigs that have been developed in-house for each project. Our test technicians qualify each circuit to meet the customer’s specifications.